The last day of service for the Illini Gadget Garage for Fall 2018 will be November 9. Whether you need some guidance with troubleshooting, know that you’ll need a new part for your device, but aren’t sure which one or how to find out, or if you need access to tools and moral support to make a repair, get your appointments made or email your questions!

We’re entering the time of year when interest in appointments slows down due to students concentrating on final projects and the general distraction of impending holidays for everyone in the community. Given that, we thought it would be a good time to close down.

Also, an important transition is ahead of the Illini Gadget Garage. The Illinois Sustainable Technology Center (ISTC), which helped launch the project and has coordinated it for the last few years, will not continue its coordination after this semester, in order to focus resources on other projects. The possibility of the project being “adopted” by another unit on campus is being investigated, and hopefully that will mean the IGG will reopen again sometime in the near future. However, if another unit does not assume coordination, the project will sadly end.

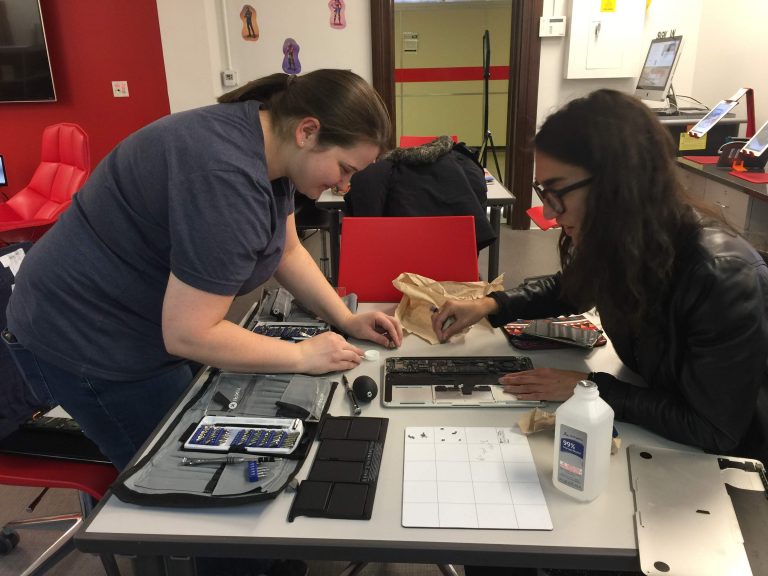

On behalf of myself, Amanda Elzbieciak (our fabulous workshop manager), past staff and volunteers, and co-founders Martin Wolske and William Bullock, we have greatly appreciated the opportunity to assist the campus and surrounding community with collaborative repair. Earlier this week, I spoke about sustainable electronics and electronic product stewardship for a group of employees of one of ISTC’s clients. In that presentation, I asserted my belief (backed by the evidence of the myriad social and environmental impacts of electronics covered elsewhere in my talk) that because of all the natural and human resources invested in the manufacture of electronics, the most important thing you can do as an individual to reduce the negative impacts of the electronic devices is to keep devices that already exist in service for as long as possible. Having been able, through the Illini Gadget Garage project, to assist members of the UI and broader Champaign-Urbana area to realize that repair, rather than replacement, of devices with minor damage or performance issues is a feasible option regardless of income or tech savvy, has been a sincere honor. I truly hope that whatever becomes of this particular project, that spirit of repair and reuse continues to thrive and grow in our community.

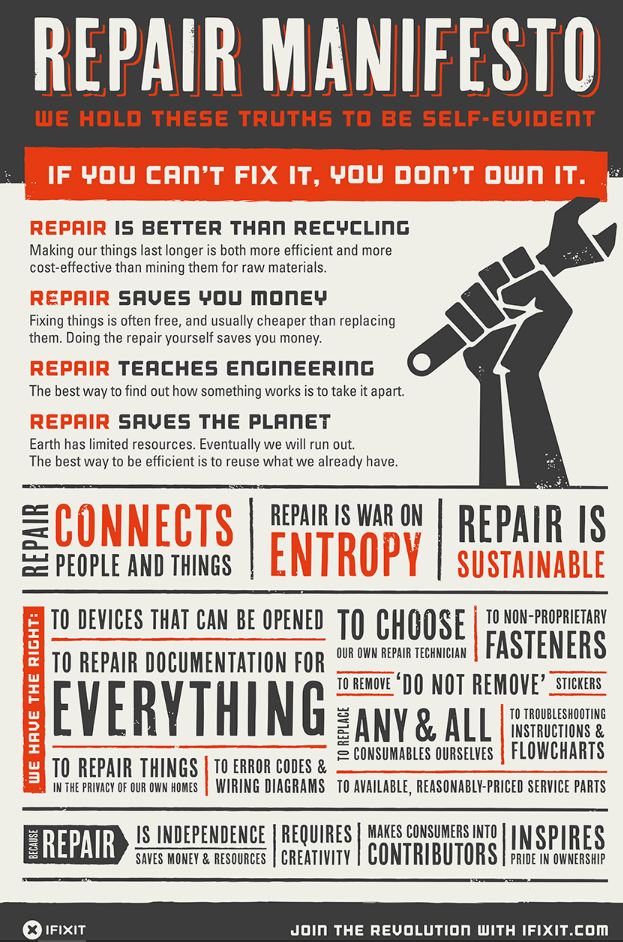

So keep your fingers crossed that the project continues without me or ISTC. If you represent a campus unit that might be interested in the project, contact me (but keep in mind you will not be the first unit to express interest). And as always, if you represent a group or company interested in starting your own project focused on reuse and repair, don’t hesitate to reach out to me for assistance. That remains part of what I do as a member of ISTC’s Technical Assistance team. Watch this space and our social media for updates. Keep fixing, Illini! In the meantime, take some inspiration from the iFixit Repair Manifesto:

Opinions are those of the author alone and mention of businesses or organizations are for information purposes only and should not be construed as an endorsement by ISTC or the University of Illinois.